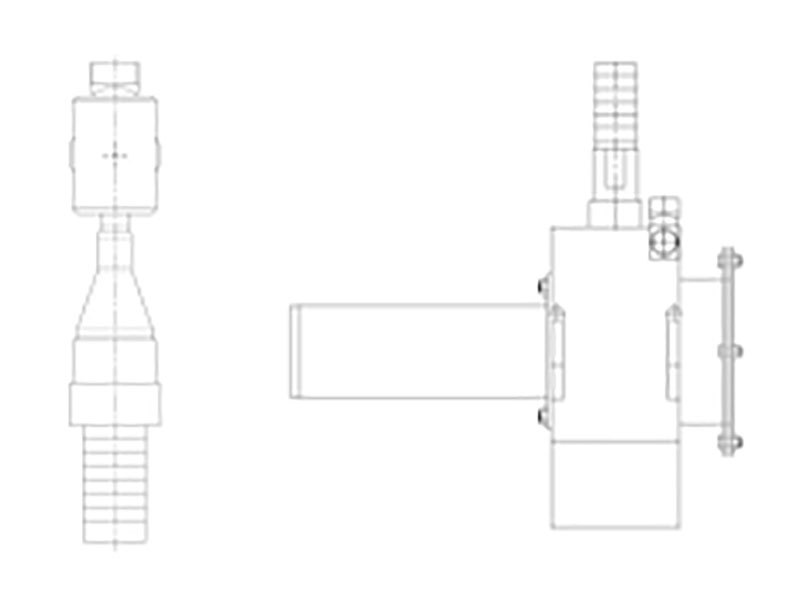

Mine drilling anti spray dust collector

Keyword:

Category:

DESCRIPTION

The BA-FP73 anti spray dust collector adopts a simple gas slag collection box, which dynamically collects drilling gas slag through the simple box. Its main functions include anti spray and dust reduction. Blowout prevention: Effectively block small gas spray holes and prevent accidents such as gas exceeding limits caused by spray holes. Dust removal: Preliminary dust prevention is achieved by spraying water through the gas residue collection box. By using a compressed air injection device or extraction pipeline, small dust is directed and drained to achieve dust reduction in the drilling construction environment. This device can timely and effectively prevent small spray holes and simple dust removal during drilling construction.

When drilling normally, the gas and coal slag inside the borehole enter the anti spray and dust removal box along with the borehole. The box is treated with water spraying to achieve preliminary dust prevention and removal. Most of the gas and dust are then directed through drainage to prevent gas exceeding limits caused by small gas flows and reduce dust pollution on the drilling site.

Technical characteristics

Reduce the concentration of dust generated during drilling.

During the drilling process, it can prevent gas exceeding the limit caused by the spray hole.

Prevent coal and rock particles from being sprayed out at high speeds during drilling, which can cause injuries to people.

Collect gas during the drilling process through the injection device to reduce gas emissions.

The device is easy to install and easy to use.

Application Scenario

The ventilation of underground tunnels in coal mines is good;

The workspace is well supported and the box can be fixed before being added;

The box can be connected to pressure air pipes, water pipes, and extractors.

The main purpose is to prevent and remove dust from small gas spray holes during the construction process of layered drilling.

| Performance index | Parameter |

| Sealing hole diameter |

108mm |

| Drill pipe diameter |

73mm |

| Drill diameter |

50mm-94mm |

| Ultimate blowout prevention capacity |

<6m3/min(Pressure air injection and blowout prevention) The amount of spray prevention in the extraction pipeline network needs to be determined based on the negative pressure at the extraction orifice |

| Rated working wind pressure |

0.55MPa |

| Rated wind pressure induced flow rate |

4-6m2/min(Pressure air injection and blowout prevention) |

| Dustproof | Using spray holes to reduce dust and directing other dust to other areas |

| Blowout and dust removal box | Height: 350mm, width: 300mm, weight: 15kg |

| Ejector | Height: 340mm, width: 210mm, weight: 3.5kg |

Related Products

Product Quotation